Product Center

Contact Us

Contact person: Mr. Wang

dgkesion@163.com

zhouyi@kesionots.com(Sales Department)

No. 1, Building 1, Zhenrong Road, Wusha, Chang'an Town, Dongguan City, Guangdong Province

High and low temperature shock test chamber (split type)

The high and low temperature shock testing chamber (split type) adopts a split design, with the chamber system working part and the working chamber part designed as independent modules, customized as needed. The test system structure can be divided into two parts: a high-temperature tank (preheating area) and a low-temperature tank (pre-cooling area). By controlling the rapid movement of the mobile basket (test sample placement area) to the low-temperature tank or the high-temperature tank, rapid cold and hot shock testing is achieved.

Category:

Thermal shock test chamber

Keyword:

Kexun

Mobile:18688631772 18925806499

Product Introduction

Product Specifications: Available in standard capacities from 17L to 1000L, with non-standard customization options available

Product Introduction: The High and Low Temperature Shock Test Chamber (Split Type) adopts a split design, with the chamber system working section and the working section designed as independent modules, customizable as needed. The test system structure can be divided into two parts: a high-temperature tank (preheating area) and a low-temperature tank (pre-cooling area). By controlling the movement of the mobile basket (test sample placement area) to quickly move to the low-temperature tank or high-temperature tank, rapid cold and hot shock testing is achieved.

Product Alias: Split-type high and low temperature shock test chamber, split cold and hot shock chamber, segmented air-cooled high and low temperature shock test chamber, grouped two-chamber temperature shock test chamber...

High and Low Temperature Shock Test Chamber (Split Type) : Adopts a split design, with the chamber system working section and the working section designed as independent modules, customizable as needed. The test system structure can be divided into two parts: a high-temperature tank (preheating area) and a low-temperature tank (pre-cooling area). By controlling the movement of the mobile basket (test sample placement area) to quickly move to the low-temperature tank or high-temperature tank, rapid cold and hot shock testing is achieved. Suitable for assessing the ability of complete machines, components, parts, and materials to withstand rapid temperature changes.

Application Areas: Semiconductor chips, scientific research institutions, quality inspection, new energy, optoelectronic communication, aerospace military industry, automotive industry, LCD display, medical and other technological industries.

Standards Met: GJB 150.3、GJB 150.4、GJB150.5、GB/T 2423.1、GB/T 2423.2、JESD22-A106B、MIL-STD-810G、MIL-STD-202G

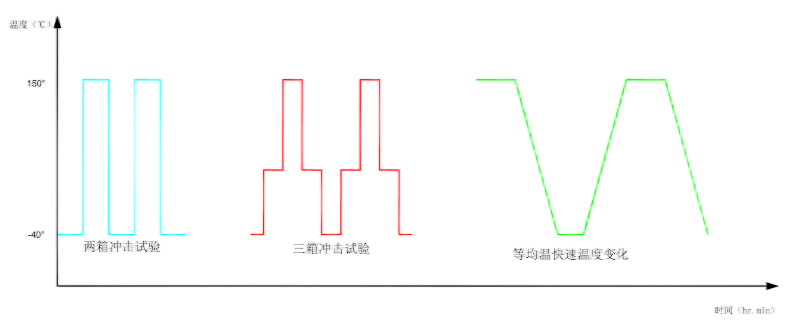

Temperature Cycle Curve Diagram:

Features

Split structure design, flexible movement, not limited by elevators or doorways.

2-temperature zone shock method. Test samples are moved up and down in the basket for cold and hot shock testing, minimizing the thermal load during cold and hot shock and shortening the temperature recovery time.

Can continuously shock 1000 times without defrosting, ultra-low defrosting frequency, reducing waiting time, and greatly improving test efficiency.

Using electronic expansion valve technology + innovative control system, the product is highly energy-efficient (>45%) and the lifespan is extended by more than 1/3.

The cold and hot shock mechanism movement time is within 5 seconds, complying with MIL, IEC, JIS and other standards.

High-specification professional design, customizable baskets with horizontal left and right movement, three-chamber (air exchange type) and immersion type shock methods for cold and hot shock test chambers according to test requirements and sample size.

Complies with temperature cycle TC, cold and hot shock test, thermal stress test, and performance testing.

*Customizable non-standard models with any specifications*

High and Low Temperature Shock Test Chamber (Split Type) | ||||||||

Model | KS-GDW2-49L | KS-GDW2-100L | KS-GDW2-150L | KS-GDW2-250L | KS-GDW2-450L | KS-GDW2-1000L | ||

Basket Capacity (L) | 49 L | 100 L | 150 L | 250 L | 450 L | 1000 L | ||

Structure Size | Basket Dimensions | Width | 400 | 500 | 600 | 700 | 800 | 1000 |

Depth | 350 | 500 | 500 | 600 | 800 | 1000 | ||

Height | 350 | 400 | 500 | 600 | 700 | 1000 | ||

Viewing Window Size | Width W * Height H | 210*300 | 320*430 | 320*430 | 320*430 | 320*430 | 390*540 | |

Performance Indicators | High Temperature Tank | Temperature Range | +60℃~+200℃ | |||||

Heat Storage Time | RT (Room Temperature) ~ +200℃, ≤30min | |||||||

Low Temperature Tank | Temperature Range | -10℃~-80℃ | ||||||

Pre-cooling Time | RT (Room Temperature) ~ -75℃, ≤50min | |||||||

Basket | Temperature Shock Range | A: -40~+150℃,B: -55~+150℃,C: -65~+150℃ | ||||||

Temperature Fluctuation | ≤±0.5℃ | |||||||

Temperature Uniformity | ≤2.0℃ | |||||||

Temperature Deviation | ≤±2.0℃ | |||||||

Basket Conversion Time | 5s | |||||||

Temperature Recovery Time | ≤ 5min | |||||||

Total Power (KW) | 7.75 | 12.5 | 21.25 | 28.35 | 37.9 | 50 | ||

Test Method | Pneumatic switching, vertical up and down movement of the basket | |||||||

Noise (dB) | ≤72 | ≤72 | ≤72 | ≤75 | ≤75 | ≤75 | ||

Number of Cycles Without Defrosting | 1000 times (optional without defrosting during the process) | |||||||

Cooling Method | Air-cooled or water-cooled | |||||||

Chamber Material | Inner Chamber | SUS #304 Stainless Steel | ||||||

Outer Chamber | Cold-rolled steel plate + double-sided electrostatic spraying process, Kexun standard blue-gray | |||||||

Insulation | Ultrafine glass wool | |||||||

Operating ambient temperature | Air cooling ambient temperature requirement 5~+30℃/Water cooling ambient temperature requirement +5~+40℃ (water cooling requires a water tower or chiller) | |||||||

Standard accessories | 1 heat-insulating glass viewing window, two sample racks, 50mm diameter test line hole * 1, power cord, instruction manual | |||||||

Power supply | AC380V±10% 50Hz,3P5W | |||||||

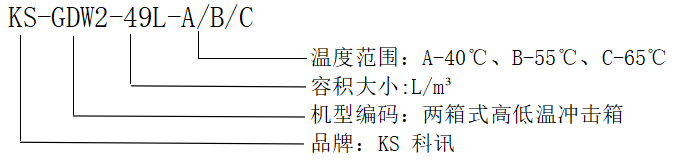

Model description |

| |||||||