Product Center

Contact Us

Contact person: Mr. Wang

dgkesion@163.com

zhouyi@kesionots.com(Sales Department)

No. 1, Building 1, Zhenrong Road, Wusha, Chang'an Town, Dongguan City, Guangdong Province

Liquid tank type thermal shock test chamber

Tank Temperature Shock Test Chamber, using stirred liquid medium instead of circulating air medium for heat transfer, allows samples to quickly switch between liquid tanks of different temperatures to evaluate their durability and stability under temperature changes, meeting stringent testing requirements.

Category:

Thermal shock test chamber

Keyword:

Kexun

Mobile:18688631772 18925806499

Product Introduction

Product Introduction: The Tank Temperature Shock Test Chamber uses a stirred liquid medium instead of circulating air for heat transfer, allowing samples to quickly switch between different temperature liquid tanks to evaluate their durability and stability under temperature changes. It can meet stringent testing requirements.

Product Alias: Liquid oil thermal shock test chamber, liquid high and low temperature shock test chamber, liquid thermal shock test chamber, tank thermal shock test chamber, hot and cold oil shock chamber, double-cylinder oil bath, hot oil test machine, liquid immersion thermal shock test chamber

Tank Thermal Shock Test Chamber: Thermal shock test chambers include air-door (static) type, basket (mobile) type, liquid medium type, and airflow type. Their temperature change rate is usually >30°C/min, simulating rapid changes in ambient temperature to test the adaptability of products to rapid changes in ambient temperature. They can also test samples for chemical changes or physical damage caused by thermal expansion and contraction in the shortest time, and in some cases are used for environmental stress screening tests.

► Composed of a high-temperature liquid tank (preheating zone) and a low-temperature liquid tank (pre-cooling zone).

► The test is performed by switching between two independent fluid baths to achieve hot and cold cycle shock, with automatic mechanical suspension moving up and down and left and right to the high and low temperature liquid tanks.

► Different liquid media (D02/D02TS fluorinated oil, silicone oil, ethylene glycol, pure water, etc.) are provided according to different samples.

► Reinforced sealing design reduces medium evaporation loss, efficient and practical oil-liquid separation and recovery design.

► Complies with US military standard MIL-STD-883E and meets thermal stress screening tests.

Application Areas: Printed circuit boards, semiconductor chips, silicone rubber, ceramics, polymer materials...

Standards Met : GB/T4677-2002 9.2.1,IPC-TM-650 2.4.6,,MIL-STD-883E,MIL-STD-202G,JIS C 0025

Technical specifications can be customized

|

Tank Thermal Shock Test Chamber |

|||||||

|

Model |

KS-LR2YC-22L |

KS-LR2YC-5.2L |

KS-LR2YC-10L |

KS-LR2YC-15L |

KS-LR2YC-30L |

||

|

Basket Capacity (L) |

22 L |

4.5 L |

10 L |

15 L |

30 L |

||

|

Structure Size |

Basket Dimensions |

Width W |

120 |

500 |

600 |

700 |

800 |

|

Depth D |

120 |

400 |

500 |

600 |

800 |

||

|

Height H |

150 |

500 |

500 |

600 |

700 |

||

|

Performance Indicators |

High Temperature Liquid Tank |

Temperature Range |

+60℃~+200℃ |

||||

|

Preheat Time |

RT (Room Temperature) ~+150℃, ≤45min |

||||||

|

Low Temperature Liquid Tank |

Temperature Range |

-10℃~-80℃ |

|||||

|

Pre-cool Time |

RT (Room Temperature) ~-65℃, ≤60min |

||||||

|

Test Basket |

Temperature Shock Range |

A:-40~+180℃,B:-55~+180℃,C:-65~+180℃ |

|||||

|

Temperature Fluctuation |

≤±0.5℃ |

||||||

|

Temperature Uniformity |

≤2.0℃ |

||||||

|

Temperature Deviation |

≤±2.0℃ |

||||||

|

Basket Transfer Time |

10s |

||||||

|

Temperature Recovery Time |

≤ 3min |

||||||

|

Liquid Medium |

Fluorinated oil (perfluoropolyether oil), silicone oil, pure water, ethylene glycol |

||||||

|

Number of Continuous Tests Without Defrosting |

No defrosting required |

||||||

|

System Structure |

Movable test product, with high and low temperature liquid tanks in one chamber |

||||||

|

Test Method |

Automatic mechanical suspension moves up and down and left and right to the high and low temperature liquid tanks |

||||||

|

Cooling Method |

Air cooling or water cooling |

||||||

|

Chamber Material |

Inner Chamber |

SUS #304 Stainless Steel |

|||||

|

Outer Chamber |

Cold-rolled steel plate + double-sided electrostatic spraying process |

||||||

|

Insulation |

Ultra-fine glass wool |

||||||

|

Viewing Window Size (mm) |

Width W * Height H |

500*350 |

550*350 |

600*350 |

650*400 |

650*400 |

|

|

Ambient Operating Temperature |

Air-cooled ambient temperature requirement: 5~+30℃ / Water-cooled ambient temperature requirement: +5~+40℃ (Water cooling requires a cooling tower or chiller). |

||||||

|

Standard Accessories |

One heat-insulated glass viewing window, power cord, instruction manual |

||||||

|

Power Supply |

AC380V±10% 50Hz,3P5W |

||||||

|

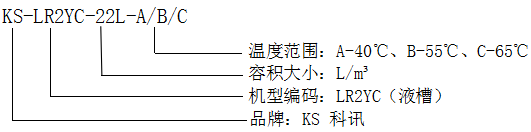

Model Description |

|

||||||

Previous Page

Next Page