Product Center

Contact Us

Contact person: Mr. Wang

dgkesion@163.com

zhouyi@kesionots.com(Sales Department)

No. 1, Building 1, Zhenrong Road, Wusha, Chang'an Town, Dongguan City, Guangdong Province

Three-chamber thermal shock test chamber

The English name for the three-zone thermal shock test chamber is "3-Zone Thermal Shock Test Chamber". It is used to test the tolerance of materials, structures, or composite materials to rapid changes between extremely high and low temperatures, determining their susceptibility to chemical changes or physical damage caused by thermal expansion and contraction in the shortest possible time.

Category:

Thermal shock test chamber

Keyword:

Kexun

Mobile:18688631772 18925806499

Product Introduction

Product Specifications: Inner box meets 49~1000L standard volume and non-standard customization

Product Introduction: The three-zone thermal shock test chamber is used to test the tolerance of materials, structures, or composite materials to continuous exposure to extremely high and low temperatures in an instant, to test the chemical changes or physical damage caused by thermal expansion and contraction in the shortest time.

Product Alias: Three-zone thermal shock chamber, high and low temperature shock test chamber three-zone, energy storage temperature shock test chamber, air-change thermal shock chamber, air-door switching three-compartment thermal shock test chamber, high and low temperature shock testing machine

Three-zone thermal shock test chamber: Thermal shock test chambers include air-door (static) type thermal shock test chambers, basket (mobile) type thermal shock test chambers, liquid medium thermal shock test chambers, and airflow thermal shock test chambers. Their temperature change rate is usually > 30°C/min, capable of simulating rapid changes in ambient temperature to assess the adaptability of products to rapid changes in ambient temperature. They can also test the chemical changes or physical damage caused by thermal expansion and contraction of samples in the shortest time, and in some cases are also used for environmental stress screening tests.

► 3-chamber shock method, energy storage temperature shock method, temperature conversion through air-door opening/closing switching.

► The sample remains stationary, without mechanical shock, facilitating power connection and external cable testing.

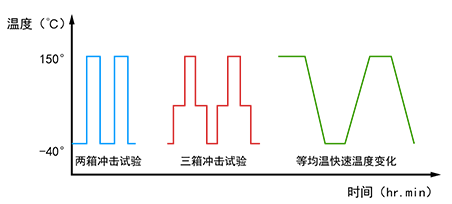

► Temperature shock method: High temperature → Normal temperature → Low temperature; Low temperature → Normal temperature → High temperature; Low temperature → High temperature; Room temperature exposure test can be performed. Two-chamber (basket) and three-chamber (energy storage) shock methods can be customized according to sample requirements.

► Meets temperature cycle TC, thermal shock, thermal stress screening, performance testing and other reliability tests.

► Uses electronic expansion valve technology, highly energy-efficient >45%.

Common Temperature Cycle Shock Curves:

Standards Met: GJB 150.3、GJB 150.4、GJB150.5、GB/T 2423.1、GB/T 2423.2、JESD22-A106B、MIL-STD-810G、MIL-STD-202G

|

Three-zone Thermal Shock Test Chamber |

||||||||

|

Model |

KS-LR3-49L |

KS-LR3-100L |

KS-LR3-150L |

KS-LR3-250L |

KS-LR3-450L |

KS-LR3-1000L |

||

|

Working Chamber Volume (L) |

49 L |

100 L |

150 L |

250 L |

450 L |

1000 L |

||

|

Structure Size |

Chamber Dimensions |

Width W |

350 |

500 |

600 |

700 |

800 |

1000 |

|

Depth D |

350 |

400 |

500 |

600 |

800 |

1000 |

||

|

Height H |

400 |

500 |

500 |

600 |

700 |

1000 |

||

|

Performance Indicators |

Hot zone |

Temperature Range |

+60℃~+200℃ |

|||||

| Hot time |

RT (Room Temperature) ~+200℃, ≤30min |

|||||||

|

Cold zone |

Temperature Range |

-10℃~-80℃ |

||||||

| Cold time |

RT (Room Temperature) ~-75℃, ≤50min |

|||||||

| Working zone |

Temperature Shock Range |

A:-40~+150℃,B:-55~+150℃,C:-65~+150℃ |

||||||

|

Temperature Fluctuation |

≤±0.5℃ |

|||||||

|

Temperature Uniformity |

≤2.0℃ |

|||||||

|

Temperature Deviation |

≤±2.0℃ |

|||||||

|

Air Door Switching Time |

5s |

|||||||

|

Temperature Recovery Time |

≤ 5min |

|||||||

|

Test Method |

Air door switching type, the sample remains stationary. |

|||||||

|

Number of Continuous Tests Without Defrosting |

1000 times (optional without defrosting during the process) |

|||||||

|

Cooling Method |

Air cooling or water cooling |

|||||||

|

Cabinet Material |

Inner Chamber |

SUS #304 Stainless Steel |

||||||

|

Outer Chamber |

Cold-rolled steel plate + double-sided electrostatic spraying process |

|||||||

|

Insulation |

Ultra-fine glass wool |

|||||||

|

Noise (dB) |

≤72 |

≤72 |

≤72 |

≤75 |

≤75 |

≤75 |

||

|

Operating Power (KW) |

7.75 |

12.5 |

21.5 |

28 |

37.9 |

50 |

||

|

Viewing Window Size |

As per design requirements |

|||||||

|

Ambient Operating Temperature |

Air-cooled ambient temperature requirement 5~+30℃/Water-cooled ambient temperature requirement +5~+40℃ (water cooling requires a water tower or chiller) |

|||||||

|

Standard Accessories |

Two sample racks, test line hole diameter 50mm*1, a set of silicone rubber stoppers, power cord, instruction manual |

|||||||

|

Power Supply |

AC380V±10% 50Hz,3P5W |

|||||||

|

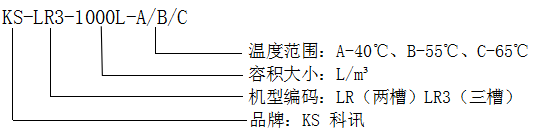

Model Description |

|

|||||||

Customizable specifications for non-standard models

Previous Page