Product Center

Contact Us

Contact person: Mr. Wang

dgkesion@163.com

zhouyi@kesionots.com(Sales Department)

No. 1, Building 1, Zhenrong Road, Wusha, Chang'an Town, Dongguan City, Guangdong Province

KSH Rapid Temperature and Humidity Change Test Chamber

Used to detect the performance of products under rapid temperature changes and extreme temperatures. Mainly used in semiconductor chips, scientific research institutions, quality inspection, new energy, optoelectronic communication, aerospace military industry, automotive industry, LCD display, medical and other technology industries.

Category:

Rapid temperature change test chamber

Keyword:

Kexun

Mobile:18688631772 18925806499

Product Introduction

Product Specifications: Meets 150~4600L standard volume and non-standard customization

Product Introduction: Used to detect the performance of products under rapid temperature changes and extreme temperatures. Mainly used in semiconductor chips, scientific research institutions, quality inspection, new energy, optoelectronic communication, aerospace military industry, automotive industry, LCD display, medical and other technological industries.

Product Alias: Rapid temperature change (humidity and heat) test chamber, rapid temperature change high and low temperature humidity test chamber, rapid change (temperature cycle) test chamber, temperature and humidity rapid cycle test chamber, ESS environmental stress screening test chamber, rapid temperature change chamber, rapid temperature change chamber, temperature transient test chamber, rapid temperature change chamber

Kexun Rapid Temperature Change (Humidity and Heat) Test Chamber: Suitable for electronic and electrical product environmental stress screening (ESS) tests, and temperature stress detection, temperature and humidity screening, reliability testing, performance testing, weathering testing, high and low temperature storage, etc., under conditions of rapid or gradual temperature changes. Common temperature change rates include 5℃/min, 10℃/min, 15℃/min, 20℃/min, and 25℃/min.

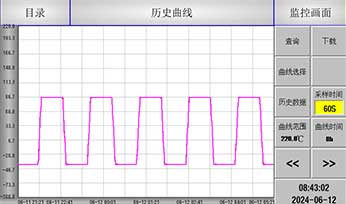

1. The product meets the requirements of temperature setpoint change (linear) and average (non-linear) change.

2. Meets the temperature change rate requirement of 5~30℃/min.

3. Optional liquid nitrogen function, humidity and heat function, anti-condensation function, etc. can be selected.

4. Using electronic expansion valve technology + innovative control system, the product is highly energy-efficient >30%.

I. Application Fields: Semiconductor chips, scientific research institutions, quality inspection, new energy, optoelectronic communication, aerospace military industry, automotive industry, LCD display, medical and other technological industries.

II. Temperature Change Operation Curve:

Product Features

Test standards met: GB/T 2423.1 Low temperature test method, GJB 150.3 High temperature test, GB/T 2423.2 High temperature test method, GJB 150.4 Low temperature test, GB/T2423.34 Humidity and heat cycle test method, GJB 150.9 Humidity and heat test, IEC60068-2 Temperature and humidity test method, MIL-STD-202G-103B Humidity test

'Customizable non-standard models with any specifications and parameters'

|

Linear-Rapid Temperature Test Chamber |

||||||||||||||||||||||||||||||||||||

|

Model |

X: Linear Humidity F: Non-linear Humidity |

KS-Without Humidity (Dry Heat) |

||||||||||||||||||||||||||||||||||

|

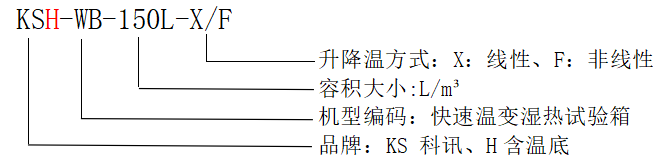

KS-WB-150L-X/F |

KS-WB-225L-X/F |

KS-WB-512L-X/F |

KS-WB-1000L-X/F |

KS-WB-2400L-X/F |

KS-WB-3400L-X/F |

|||||||||||||||||||||||||||||||

|

KSH-With Humidity (Humidity and Heat) |

||||||||||||||||||||||||||||||||||||

|

KSH-WB-150L-X/F |

KSH-WB-225L-X/F |

KSH-WB-512L-X/F |

KSH-WB-1000L-X/F |

KSH-WB-2400L-X/F |

KSH-WB-3400L-X/F |

|||||||||||||||||||||||||||||||

|

Internal Volume (L) |

150L |

225L |

512L |

1000L |

2400L |

3400L |

||||||||||||||||||||||||||||||

|

Internal Dimensions (mm) |

Width W |

500 |

600 |

800 |

1000 |

1300 |

1500 |

|||||||||||||||||||||||||||||

|

Depth D |

500 |

500 |

800 |

1000 |

1400 |

1500 |

||||||||||||||||||||||||||||||

|

Height H |

600 |

750 |

800 |

1000 |

1300 |

1500 |

||||||||||||||||||||||||||||||

|

Heating and Cooling Rate (℃/min) |

5 |

10 |

15 |

20 |

25 |

5 |

10 |

15 |

20 |

25 |

5 |

10 |

15 |

20 |

25 |

5 |

10 |

15 |

20 |

25 |

5 |

10 |

15 |

20 |

25 |

5 |

10 |

15 |

20 |

25 |

||||||

|

Performance Indicators |

|

Temperature Performance Indicators |

||||||||||||||||||||||||||||||||||

|

Temperature Range |

-70℃ ~ +180℃ |

|||||||||||||||||||||||||||||||||||

|

Rapid Temperature Change Range |

A:-40 ~+125℃,C:-55 ~+125℃ |

|||||||||||||||||||||||||||||||||||

|

Temperature Uniformity |

≤2.0℃ |

|||||||||||||||||||||||||||||||||||

|

Temperature Fluctuation |

≤+0.5℃ |

|||||||||||||||||||||||||||||||||||

|

Temperature Deviation |

≤2.0℃ |

|||||||||||||||||||||||||||||||||||

|

|

Humidity Performance Indicators |

|||||||||||||||||||||||||||||||||||

|

Humidity Range |

10%RH~90%RH,(5%~98%RH; special conditions require customization) |

|||||||||||||||||||||||||||||||||||

|

Humidity Uniformity |

≤3.0%RH |

|||||||||||||||||||||||||||||||||||

|

Humidity Fluctuation |

≤+2.0%RH |

|||||||||||||||||||||||||||||||||||

|

Humidity Deviation |

+3.0%RH (>75%RH);+5.0%RH (≤75%RH) |

|||||||||||||||||||||||||||||||||||

|

Cabinet Material |

Inner Chamber |

SUS#304 Stainless Steel |

||||||||||||||||||||||||||||||||||

|

Outer Chamber |

Cold-rolled steel plate + double-sided electrostatic spraying process |

|||||||||||||||||||||||||||||||||||

|

Insulation Layer |

Ultra-fine glass wool |

|||||||||||||||||||||||||||||||||||

|

Viewing Window Size (mm) |

Width W*Height H |

210*300 |

280*350 |

360*510 |

360*510 |

360*510 |

360*510 |

|||||||||||||||||||||||||||||

|

Noise |

≤75 (dB) |

|||||||||||||||||||||||||||||||||||

|

Cooling Method |

Water cooling (water temperature 7~28℃, water pressure 0.1~0.4Mpa) |

|||||||||||||||||||||||||||||||||||

|

Environmental Requirements |

Environmental humidity: 5~35℃, relative humidity ≤85%RH, no strong vibration, electromagnetic radiation shielding, no dust or corrosive substances around |

|||||||||||||||||||||||||||||||||||

|

Standard Configuration |

One observation window (double-layer hollow tempered conductive glass), one test hole θ50*θ100mm (located on the left), a two-layer sample rack, one box interior photographic lamp (LED light), one water supply tank, one psychrometric band for wet bulb, four small casters, one power cord, and one instruction manual. |

|||||||||||||||||||||||||||||||||||

|

Power Supply |

AC380V±10%,50Hz±1 three-phase four-wire + ground wire (3/N/PE), ground resistance less than 4Ω |

|||||||||||||||||||||||||||||||||||

|

Model Description |

|

|||||||||||||||||||||||||||||||||||

Previous Page