Product Center

Contact Us

Contact person: Mr. Wang

dgkesion@163.com

zhouyi@kesionots.com(Sales Department)

No. 1, Building 1, Zhenrong Road, Wusha, Chang'an Town, Dongguan City, Guangdong Province

HAST high-pressure accelerated life aging chamber (double-layer type)

The HAST high-pressure accelerated life aging chamber is used to evaluate the environmental resistance of electronic components, PCBs, chips, etc., under high temperature, high humidity, and high pressure conditions. By accelerating the failure process, the acceleration factor is between tens and hundreds of times. This type of extreme accelerated simulation reliability test facilitates the determination of the limit operating conditions of products or devices, making it easier to discover product failure modes in advance and shortening the life test time of products or systems, thus saving time for mass production verification.

Category:

PCT accelerated aging test chamber

Keyword:

Kexun

Mobile:18688631772 18925806499

Product Introduction

Product Description: The HAST high-pressure accelerated life aging chamber is used to evaluate the environmental resistance of electronic components, PCBs, chips, etc., under high temperature, high humidity, and high pressure conditions. By accelerating the failure process, the acceleration factor is between tens and hundreds of times. This type of extreme accelerated simulation reliability test facilitates the determination of the limit operating conditions of products or devices, making it easier to discover product failure modes in advance and shorten the life test time of products or systems, thus saving time for mass production verification.

Product Alias: Double-layer HAST high-pressure accelerated life aging chamber, two-slot HAST accelerated life test device, double-chamber HAST aging chamber, two-layer HAST high-pressure accelerated aging chamber

Kexun Double-Layer HAST High-Pressure Accelerated Life Aging Chamber: English Name: 2-Zone HAST CHAMBER, used for high-pressure, high-temperature, unsaturated/saturated humid heat, and other accelerated life reliability tests for IC packaging, semiconductors, microelectronic chips, magnetic materials, and other electronic components.

► Efficient dual-chamber design, kesionots advanced HAST equipment integrates high-temperature and high-humidity 85℃/85%R.H, 95℃/95%R.H, PCT, and HAST functions.

► Independent steam generation chamber to prevent steam from directly impacting the product, preventing local damage to the product.

► Extra-long experimental operation time; the equipment can operate continuously for 400+ hours.

► Rapid exhaust mode, exhaust cold air before the test; cold air exhaust design during the test (exhaust air inside the test barrel) improves pressure stability and reproducibility.

AEC Q101

JIS C0096-2

GB/T2423.40-1997 Electrical and Electronic Products Environmental Test Part 2: Test Method Cx: Constant Humid Heat of Unsaturated High-Pressure Steam

IEC60068-2-66-1994 Environmental Test. Part 2-66: Test Method. Test Cx: Steady-state humid heat

JESD22-A100 Cyclic Temperature and Humidity Shift Life

JESD22-A101 Steady-State Temperature, Humidity/Bias, Life Test (Temperature, Humidity, and Bias Life)

JESD22-A102 High-Pressure Steam Test (Accelerated Moisture Resistance Penetration)

JESD22-A108 Temperature, Bias Voltage, and Operating Life

JESD22-A110 HAST High-Accelerated Temperature and Humidity Stress Test

JESD22-A118 Temperature and Humidity Unbiased High-Accelerated Stress Test UHAST (Unbiased Voltage Unsaturated High-Pressure Steam) Regulations

|

HAST High-Pressure Accelerated Life Aging Chamber (Dual-Chamber Type) |

||

|

Model |

KS-2HAST-35 |

|

|

Inner Chamber Dimensions Single Chamber |

Diameter φ |

350 |

|

Depth D |

450 |

|

|

Outer Chamber Dimensions |

Width W |

700 |

|

Depth D |

1000 |

|

|

Height H |

1900 |

|

|

Performance Indicators |

Temperature Range |

A: +100~+143℃; B: +100~+156℃ |

|

Humidity Range |

60%~100%RH |

|

|

Pressure Range |

A: 0.2~3kg/cm² (0.018~0.294Mpa); B: 0.2~4kg/cm² (0.018~0.394Mpa) |

|

|

Temperature Uniformity |

≤±2℃ |

|

|

Temperature Fluctuation |

≤±0.5℃ |

|

|

Humidity Fluctuation |

≤±2 % R.H |

|

|

Humidity Deviation |

≤±3 % R.H |

|

|

Temperature Deviation |

≤±2℃ |

|

|

Pressure Deviation |

≤±2Kpa |

|

|

Heating Time |

Room temperature~+ 143℃ about 45 min; Room temperature~+ 156℃ about 55 min |

|

|

Pressurization Time |

Normal pressure~3kg/cm² about 35 min, external gas source pressurization: about 5 min |

|

|

Power |

5.6KW |

|

|

Chamber Material |

Inner Chamber |

SUS #316 Stainless Steel |

|

Outer Chamber |

Cold-rolled steel plate + double-sided electrostatic spraying process |

|

|

Insulation |

Ultra-fine glass wool |

|

|

Noise |

≤60 (dB) |

|

|

Controller |

7-inch color touch screen controller (with pressure, temperature, and humidity display, with RS-485 or RS-232 communication, USB data baking) |

|

|

Resolution |

Temperature: 0.01℃; Humidity: 0.1%RH; Pressure: 0.1 kg/cm²; |

|

|

Pressurization Method |

1. Boiler steam pressurization; 2. External gas pressurization |

|

|

BIAS Bias Terminal |

With bias terminal (Please specify when ordering options). |

|

|

Conditions of Use |

Ambient temperature: +5℃~+35℃; Ambient humidity: ≤85%RH; Ambient atmospheric pressure: 86KPa~106KPa |

|

|

Power Supply |

AC220V 50/60Hz |

|

|

Protective Device |

1. Overtemperature protection, 2. Fan overload protection, 3. Cabinet door pressure protection, 4. Water shortage protection, 5. Overflow protection, 6. Heater dry-burn protection, 7. Heater overload protection, 8. Power failure protection, 9. Overcurrent protection, 10. Short circuit and leakage protection |

|

|

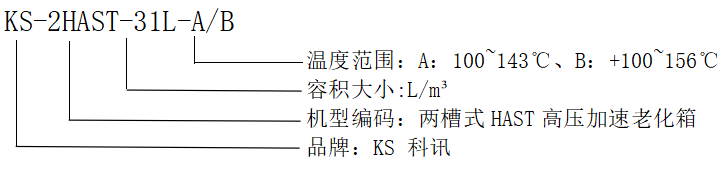

Model Description |

|

|

Previous Page