Product Center

Contact Us

Contact person: Mr. Wang

dgkesion@163.com

zhouyi@kesionots.com(Sales Department)

No. 1, Building 1, Zhenrong Road, Wusha, Chang'an Town, Dongguan City, Guangdong Province

BHAST (Bias-Temperature Stress Test) Accelerated Aging Test Chamber

To evaluate the operational reliability of non-hermetic packaged IC devices (solid-state devices) under high temperature and high humidity conditions, and to perform high-accelerated stress life aging tests on chips, semiconductors, and other components with temperature, humidity, and bias voltage.

Category:

PCT accelerated aging test chamber

Keyword:

Kexun

Mobile:18688631772 18925806499

Product Introduction

Product Specifications: Meets 35~55L standard capacity and other non-standard customized models

Product Introduction: Used to evaluate the operational reliability of non-hermetic packaged IC devices (solid-state devices) under high temperature and high humidity conditions, and to perform high-accelerated stress life aging tests on chips, semiconductors, and other components with temperature, humidity, and bias voltage.

Product Alias: BHAST, Bias High Accelerated Life Test Chamber, Temperature and Humidity Bias Life Aging Test Chamber, High Temperature and High Humidity Bias Humid Heat Aging Chamber

I. Test Standards Met:

AEC Q101 (Automotive Grade Chips)

JIS C0096-2

GB/T2423.40-1997 Environmental Test for Electrical and Electronic Products Part 2: Test Methods Cx: Constant Humid Heat of Unsaturated High-Pressure Steam

IEC60068-2-66-1994 Environmental Testing. Part 2-66: Test Methods. Test Cx: Steady-State Humid Heat

JESD22-A100 Cyclic Temperature and Humidity Offset Life

JESD22-A101 Steady-State Temperature, Humidity/Bias, Life Test (Temperature Humidity Bias Life)

JESD22-A102 High-Pressure Steam Test (Accelerated Moisture Resistance Penetration)

JESD22-A108 Temperature, Bias Voltage, and Operating Life

JESD22-A110 HAST High Accelerated Temperature and Humidity Stress Test

II. Application Fields: PCB, LCD Board, Battery, Capacitor, Resistor, IC Semiconductor, Connector, Circuit Board, Magnetic Material, Polymer Material, EVA, Photovoltaic Component, Automotive Grade Chip

1. The inner tank uses a double-layer arc design to prevent dew condensation during the test, thus avoiding the impact of direct hot steam on the product during the test and affecting the test results.

2. Uses a high-efficiency vacuum pump to achieve the optimal pure saturated steam state in the chamber.

3. Uses a 7-inch true color touch screen, with 250 groups and 12500 segments of programs, and has USB curve data download function and RS-485 communication interface.

4. Automotive-grade silicone overall sealing strip, good airtightness, durable.

5. Automatic water replenishment function, front-mounted water level confirmation.

6. Uses dry and wet bulb sensors for direct measurement (control modes include: dry and wet bulb, unsaturated, and wet saturation, 3 modes in total).

|

BHAST (Bias) Accelerated Aging Test Chamber |

|||

|

Model |

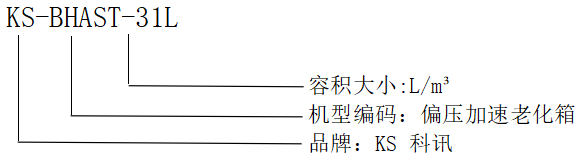

KS-BHAST-31L |

KS-BHAST-69L |

KS-BHAST-154L (Customizable) |

|

Internal Capacity (L) |

31 L |

69 L |

154 L |

|

Internal Chamber Dimensions (ΦxD) Diameter x Depth (mm) |

350x450mm |

400x550mm |

550x650mm (Customizable to larger sizes) |

|

Power |

2.8KW |

3.2KW |

4KW |

|

Weight |

252KG |

285KG |

358KG |

|

Power Supply |

AC220V 50/60Hz |

||

|

Temperature Range |

+100℃~+156℃ |

||

|

Temperature Fluctuation |

≤±0.5℃ |

||

|

Temperature Uniformity |

≤±0.5℃ |

||

|

Humidity Range |

65%~100 %R.H |

||

|

Humidity Fluctuation |

≤±2 %R.H |

||

|

Humidity Uniformity |

≤±3 % R.H |

||

|

Pressure Range |

0.2~3kg/cm² (0.018~0.294Mpa); 0.2~4kg/cm² (0.018~0.394Mpa) |

||

|

Heating Time |

Room temperature~+ 155℃ About 45 min |

||

|

Pressurization Time |

Normal pressure~3kg/cm² About 35 min. External gas source pressurization: About 5 min |

||

|

Bias Terminals |

Includes bias terminals (specify when ordering) |

||

|

Pressure Deviation |

≤±2Kpa |

||

|

Circulation Method |

Ferrofluid seal + impeller forced convection circulation method |

||

|

Pressurization Method |

1. Boiler steam pressurization; 2. External gas pressurization |

||

|

Resolution |

Temperature ±0.1℃, Humidity ±0.1%R.H, Pressure 0.01kg/cm², 0.01min |

||

|

Insulation Structure |

Inner tank: High-quality SUS316 stainless steel; Outer shell: Rolled steel plate + double-sided electrostatic spraying process; Inner tank insulation material: Ultra-fine glass wool. |

||

|

Noise |

≤60 (dB) |

||

|

Controller |

7-inch color touch screen controller (with pressure, temperature, and humidity curves, with RS-485 or RS-232 communication, USB data baking) |

||

|

Conditions of Use |

Ambient temperature: +5℃~+35℃; Ambient humidity: ≤85%RH; Ambient atmospheric pressure: 86KPa~106KPa |

||

|

Model Description |

|

||