Product Center

Contact Us

Contact person: Mr. Wang

dgkesion@163.com

zhouyi@kesionots.com(Sales Department)

No. 1, Building 1, Zhenrong Road, Wusha, Chang'an Town, Dongguan City, Guangdong Province

HAST high-pressure accelerated life aging test chamber

HAST Chamber, also known as HAST High-Pressure Accelerated Life Test Chamber, is used for automotive-grade chips, IC packaging, semiconductors, microelectronic chips, magnetic materials, and other electronic components to conduct high-pressure, high-temperature, unsaturated/saturated humid heat, and other accelerated life reliability tests. It is used in the product design stage to quickly expose product defects and weaknesses, and to test the sealing and aging performance of the product.

Category:

PCT accelerated aging test chamber

Keyword:

Kexun

Mobile:18688631772 18925806499

Product Introduction

Product Specifications: Meets standard volume selection of 31~248L and non-standard customization

Product Introduction: HAST Chamber, also known as HAST High-Pressure Accelerated Life Aging Test Chamber, is used for automotive-grade chips, IC packaging, semiconductors, microelectronic chips, magnetic materials, and other electronic components to conduct high-pressure, high-temperature, unsaturated/saturated humid heat, and other accelerated life reliability tests. It is used in the product design stage to quickly expose product defects and weaknesses, and test the sealing and aging performance of the product.

Product Alias: UHAST, High Accelerated Steady-State Humid Heat Stress Test Chamber, High-Pressure Steam Test Chamber, Unsaturated High-Pressure Steam Constant Humid Heat Chamber, BHAST

I. Test Standards Met:

AEC Q101 (Automotive Grade Chips)

JIS C0096-2

GB/T2423.40-1997 Electrical and Electronic Products Environmental Test Part 2: Test Method Cx: Constant Humid Heat of Unsaturated High-Pressure Steam

IEC60068-2-66-1994 Environmental Test. Part 2-66: Test Method. Test Cx: Steady-State Humid Heat

JESD22-A100 Cyclic Temperature and Humidity Offset Life

JESD22-A101 Steady-State Temperature, Humidity/Bias, Life Test (Temperature Humidity Bias Life)

JESD22-A102 High-Pressure Steam Test (Accelerated Moisture Resistance Penetration)

JESD22-A108 Temperature, Bias Voltage and Operating Life

JESD22-A110 HAST High-Accelerated Temperature and Humidity Stress Test

JESD22-A118 Temperature and Humidity Unbiased High-Accelerated Stress Test UHAST (Unbiased Voltage Unsaturated High-Pressure Steam)

II. Application Fields: PCB, LCD Board, Battery, Capacitor, Resistor, IC Semiconductor, Connector, Circuit Board, Magnetic Material, Polymer Material, EVA, Photovoltaic Component, Automotive Grade Chip...

Features

Kexun Instruments - HAST High-Pressure Accelerated Life Aging Chamber:

1. The inner tank adopts a double-layer arc design, which can prevent the dewdrop phenomenon during the test, thus avoiding the direct impact of superheated steam on the product during the test and affecting the test results.

2. The product meets JESD22-A100 to A118 bias (BHAST) or unbiased (UHAST) accelerated moisture resistance tests and saturated high-pressure steam (boiling) tests.

3. The product is compatible with high-accelerated temperature and humidity stress HAST aging test and high-pressure boiling PCT moisture resistance test.

|

HAST High-Pressure Accelerated Life Aging Chamber |

|||||

|

Model |

KS-HAST-31L |

KS-HAST-69L |

KS-HAST-154L |

KS-HAST-248L |

|

|

Volume (L) |

31 L |

69 L |

154 L |

248 L |

|

|

Inner Chamber Dimensions |

Diameter φ |

350 |

400 |

550 |

650 |

|

Depth D |

450 |

550 |

650 |

750 |

|

|

Outer Chamber Dimensions |

Width W |

700 |

700 |

850 |

950 |

|

Depth D |

1000 |

1000 |

1150 |

1350 |

|

|

Height H |

1710 |

1710 |

1760 |

1860 |

|

|

Performance Indicators |

Temperature Range |

A: +100~+143℃; |

|||

|

Humidity Range |

60%~100%RH |

||||

|

Pressure Range |

A: 0.2~3kg/cm² (0.018~0.294Mpa); |

||||

|

Temperature Uniformity |

≤±2℃ |

||||

|

Temperature Fluctuation |

≤±0.5℃ |

||||

|

Humidity Fluctuation |

≤±2 % R.H |

||||

|

Humidity Deviation |

≤±3 % R.H |

||||

|

Temperature Deviation |

≤±2℃ |

||||

|

Pressure Deviation |

≤±2Kpa |

||||

|

Heating Time |

Room temperature ~ +143℃ about 45 min; Room temperature ~ +156℃ about 55 min |

||||

|

Pressurization Time |

Normal pressure ~ 3kg/cm² about 35 min, external air source pressurization: about 5 min |

||||

|

Power |

2.8KW |

3.2KW |

4KW |

5KW |

|

|

Cabinet Material |

Inner Chamber |

SUS #316 Stainless Steel |

|||

|

Outer Chamber |

Cold-rolled steel plate + double-sided electrostatic spraying process |

||||

|

Insulation |

Ultra-fine glass wool |

||||

|

Noise |

≤60 (dB) |

||||

|

Controller |

7-inch color touch screen controller (with pressure, temperature and humidity, with RS-485 or RS-232 communication, USB data baking) |

||||

|

Resolution |

Temperature: 0.01℃; Humidity: 0.1%RH; Pressure: 0.1 kg/cm²; |

||||

|

Pressurization Method |

1. Boiler steam pressurization; 2. External gas pressurization |

||||

|

BIAS Bias Terminal |

Includes bias terminal (specify when ordering optional) |

||||

|

Operating Conditions |

Ambient temperature: +5℃~+35℃; Ambient humidity: ≤85%RH; Ambient atmospheric pressure requirement: 86KPa~106KPa |

||||

|

Power Supply |

AC220V 50/60Hz |

||||

|

Protective Devices |

1. Overtemperature protection, 2. Fan overload protection, 3. Cabinet door pressure protection, 4. Water shortage protection, 5. Overflow protection, 6. Heater dry-burn protection, |

||||

|

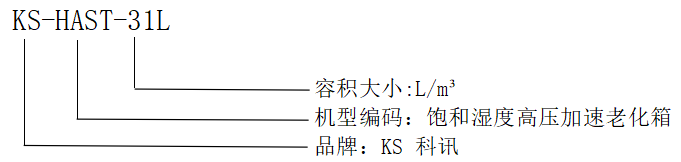

Model Description |

|

||||