Product Center

Contact Us

Contact person: Mr. Wang

dgkesion@163.com

zhouyi@kesionots.com(Sales Department)

No. 1, Building 1, Zhenrong Road, Wusha, Chang'an Town, Dongguan City, Guangdong Province

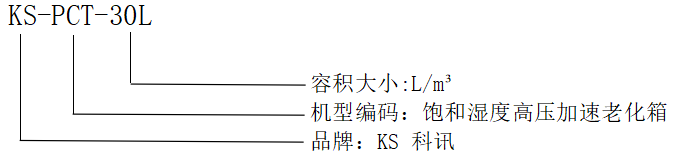

PCT (saturated) high-pressure steam cooking aging box

Used for moisture resistance assessment and robustness testing, aiming to evaluate the moisture resistance of non-hermetic packaged solid-state components under compressed and saturated moisture environments. Under high pressure and high humidity conditions, accelerate moisture penetration (plastic packaging material, chip passivation layer) or design changes (chip, electrode size) and penetration between the interface of the metal conductive layer, thereby identifying the failure mechanism inside the package.

Category:

PCT accelerated aging test chamber

Keyword:

Kexun

Mobile:18688631772 18925806499

Product Introduction

Product Specifications: Meets 31~248L standard volume selection and non-standard customization

Product Introduction: Used for moisture resistance assessment and robustness testing, the purpose is to evaluate the moisture resistance of non-hermetic packaged solid-state components under compressed and saturated moisture environments. Under high pressure and high humidity conditions, accelerate moisture penetration (plastic packaging material, chip passivation layer) or design changes (chip, touch size) and penetration between the interface of the metal conductive layer, thereby identifying the failure mechanism inside the package.

Product Alias: PCT, Saturated Steady-State Humid Heat Aging Life Test Chamber, Saturated High-Pressure Accelerated Aging Test Chamber, PCT High-Pressure Steaming Instrument, Saturated Steam Accelerated Aging Chamber, High-Temperature High-Pressure Steaming Aging Chamber Details

I. Test Standards Met:

1. GB/T10586-1989 Technical Conditions for Humid Heat Test Chamber.

2. GB2423.3-93 (IEC68-2-3) Constant Humid Heat Test.

3. MIL-STD810D Method 502.2.

4. GJB150.9-8 Temperature and Humidity Test.

5. GB2423.34-86, MIL-STD883C Method 1004.2 Temperature, Humidity, and High-Pressure Combined Cycle Test.

6. JESD22-A102 High-Pressure Steam Test (Accelerated Moisture Resistance Penetration)

II. Application Industries:

IC semiconductors, connectors, circuit boards, magnetic materials, polymer materials, EVA, photovoltaic components, defense, aerospace, automotive parts, electronic components, plastics, pharmaceuticals, circuit boards, LCDs, lamps, lighting products

1. Arc inner chamber, stainless steel circular test inner chamber structure, conforms to industrial safety container standards, and can prevent dewdrop design during the test.

2. Precise design, good airtightness, the system automatically adds enough water for the test once at the beginning of the test, and the test is never interrupted.

3. New servo flow control technology, energy saving about 30%.

4. Fluid simulation technology + innovative structural design, the equipment life is extended by more than 1/3 compared to traditional technology.

5. Large color LCD touch controller, side cable holes facilitate external load and internal data connection, and network monitoring can be performed through optional interfaces.

|

PCT (Saturated) High-Pressure Accelerated Aging Chamber |

|||||

|

Model |

KS-PCT-30L |

KS-PCT-69L |

KS-PCT-154L |

KS-PCT-248L |

|

|

Volume (L) |

31 L |

69 L |

154 L |

248 L |

|

|

Inner Chamber Dimensions |

Diameter φ |

350 |

400 |

550 |

650 |

|

Depth D |

450 |

550 |

650 |

750 |

|

|

Outer Chamber Dimensions |

Width W |

700 |

700 |

850 |

950 |

|

Depth D |

1000 |

1100 |

1150 |

1250 |

|

|

Height H |

1710 |

1710 |

1760 |

1860 |

|

|

Performance Indicators |

Temperature Range |

+100~+145℃ (Saturated Steam Temperature) |

|||

|

Humidity Range |

100%RH (Saturated Steam Humidity) |

||||

|

Pressure Range |

0.2~3kg/cm² (0.05~0.294Mpa) |

||||

|

Temperature Uniformity |

≤±2℃ |

||||

|

Temperature Fluctuation |

≤±0.5℃ |

||||

|

Humidity Fluctuation |

≤±2 % R.H |

||||

|

Humidity Deviation |

≤±3 % R.H |

||||

|

Temperature Deviation |

≤±2℃ |

||||

|

Pressure Deviation |

≤±2Kpa |

||||

|

Pressurization Time |

Approximately 45min |

||||

|

Power |

2.2KW |

2.5KW |

3.5KW |

4.5KW |

|

|

Cabinet Material |

Inner Chamber |

SUS #316 Stainless Steel |

|||

|

Outer Chamber |

Cold-rolled steel plate + double-sided electrostatic spraying process |

||||

|

Insulation |

Ultra-fine glass wool |

||||

|

Noise |

≤60 (dB) |

||||

|

Controller |

7-inch color touch screen controller (with pressure, temperature, and humidity, with RS-485 or RS-232 communication, USB data baking) |

||||

|

Resolution |

Temperature: 0.01℃; Humidity: 0.1%RH; Pressure: 0.1 kg/cm²; |

||||

|

BIAS Bias Terminal |

Customized according to user needs |

||||

|

Operating Conditions |

Ambient temperature: +5℃~+35℃; Ambient humidity: ≤85%RH; Ambient atmospheric pressure requirement: 86KPa~106KPa |

||||

|

Power Supply |

AC220V 50/60Hz |

||||

|

Protective Devices |

1. Overtemperature protection, 2. Fan overload protection, 3. Chamber door pressure protection, 4. Water shortage protection, 5. Overflow protection, 6. Heater dry-burn protection, |

||||

|

Model Description |

|

||||

Previous Page

Next Page