Product Center

Contact Us

Contact person: Mr. Wang

dgkesion@163.com

zhouyi@kesionots.com(Sales Department)

No. 1, Building 1, Zhenrong Road, Wusha, Chang'an Town, Dongguan City, Guangdong Province

HAST high-pressure accelerated aging test chamber (automatic door)

The HAST (Highly Accelerated Stress Test) high-pressure accelerated aging test chamber (with automatic door) simulates the extreme environments and high-temperature, high-humidity operating conditions that a chip may encounter during actual use to verify its reliability and lifespan. Its principle is to place the chip in a high-temperature, high-humidity environment for accelerated aging testing over a period of time, thereby improving product quality and reliability.

Category:

PCT accelerated aging test chamber

Keyword:

Kexun

Mobile:18688631772 18925806499

Product Introduction

Product Introduction: The HAST (Highly Accelerated Stress Test) high-pressure accelerated aging test chamber (with automatic door) simulates the extreme environments and high-temperature, high-humidity operating conditions that chips may encounter in actual use to test the reliability and lifespan of the chips. Its principle is to place the chips in a high-temperature, high-humidity environment for accelerated aging testing over a period of time, thereby improving product quality and reliability.

Product Alias: Automatic door HAST high-pressure accelerated aging test chamber, automatic door HAST aging test chamber, HAST high-accelerated life test chamber, automatic door HAST

Kexun HAST high-pressure accelerated aging test chamber: English name Highly Accelerated Stress Test Chamber. It simulates the high-temperature, high-humidity, high-pressure environment of chips, conducting accelerated aging tests over a certain period to verify the reliability and lifespan of chips in the shortest time, thereby improving product quality and reliability.

► Industry-first pressure test range up to 4KG,

► Automatic door design, button control for door opening and closing, with built-in pressure protection,

► Built-in self-developed PID control algorithm to ensure the accuracy of temperature, humidity, and pressure values,

► Compatible with constant wet heat (HAST) and pressure cooker test (PCT) using unsaturated high-pressure steam,

Common HAST Test Standards

|

Standard Number |

Implementation Standard |

Temperature (°C) |

Humidity (%R.h) |

Test Conditions |

Time (h) |

|

IEC60068-2-66 |

Environmental testing Part 2-66: Test methods Cx: Steady-state temperature and humidity |

110±2 |

85±S |

Any voltage |

96/192/408 |

|

GB/T2423.40 |

Environmental testing of electrotechnical products Part 2: Test methods Cx: Constant wet heat with unsaturated high-pressure steam |

110±2 |

85±S |

1-1000V |

96/192/408 |

|

GB/T4937.40 |

Semiconductor devices—Mechanical and climatic test methods—Part 4: Damp heat, steady-state, highly accelerated stress test (HAST) |

110±2 |

85±S |

1-1000V |

96/264 |

|

JIS C0096-2001 |

Environmental testing Part 2: Damp heat—Steady-state (unsaturated pressurized steam) |

110±2 |

85±S |

Any voltage |

96/192/408 |

|

JEITA(EIAJ)ED- |

Semiconductor device unsaturated steam pressure test |

110±2 |

85±S |

Continuous voltage application |

24/48/96/168/500 |

|

JPCA-ETO8 |

Printed circuit board unsaturated steam pressure test |

110±2 |

85±S |

Continuous voltage application |

96/192/408 |

|

AECQ100-Rev-E |

Automotive-grade semiconductor discrete device stress test certification |

110±2 |

85±S |

Continuous voltage application/ |

264/96 |

|

JESD22-A101C |

Steady-state temperature, humidity/bias, life test (temperature bias life) |

85±2 |

85±S |

Continuous/intermittent application |

24/168/1000 |

|

JESD22-A102E |

High-pressure steam test (accelerated moisture resistance penetration) |

121±2 |

100±S |

No bias |

24/48/96/168/240/336 |

|

JESD22-A110E |

HAST high-accelerated temperature stress test |

110±2 |

85±S |

Continuous/intermittent application |

264/96 |

|

JESD22-A1188 |

Temperature without bias voltage high-accelerated stress test UHAST (unbiased voltage unsaturated high-pressure steam) |

110±2 |

85±S |

No bias |

264/96 |

*Customizable specifications and non-standard models

|

HAST High-Pressure Accelerated Aging Test Chamber (Automatic Door) |

|||||

|

Model |

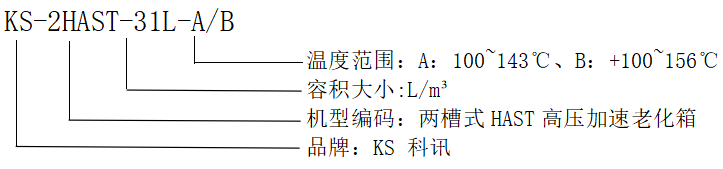

KS-2HAST-31L-A/B |

KS-2HAST-69L-A/B |

KS-2HAST-154L-A/B |

KS-2HAST-248L-A/B |

|

|

Volume (L) |

31 L |

69 L |

154 L |

248 L |

|

|

Internal Dimensions |

Diameter φ |

350 |

400 |

550 |

650 |

|

Depth D |

450 |

550 |

650 |

750 |

|

|

External Dimensions |

Width W |

700 |

700 |

850 |

950 |

|

Depth D |

1000 |

1000 |

1150 |

1350 |

|

|

Height H |

1710 |

1710 |

1760 |

1860 |

|

|

Performance Indicators |

Temperature Range |

A: +100~+143℃; |

|||

|

Humidity Range |

60%~100%RH |

||||

|

Pressure Range |

A: 0.2~3kg/cm² (0.018~0.294Mpa); |

||||

|

Temperature Uniformity |

≤±2℃ |

||||

|

Temperature fluctuation |

≤±0.5℃ |

||||

|

Humidity fluctuation |

≤±2 % R.H |

||||

|

Humidity deviation |

≤±3 % R.H |

||||

|

Temperature deviation |

≤±2℃ |

||||

|

Pressure deviation |

≤±2Kpa |

||||

|

Heating-up time |

Room temperature~+ 143℃ approximately 45 min;Room temperature~+ 156℃ approximately 55 min |

||||

|

Pressurization time |

Normal pressure~3kg/cm² approximately 35 min, external gas source pressurization: approximately 5 min |

||||

|

Power |

2.8KW |

3.2KW |

4KW |

5KW |

|

|

Cabinet material |

Inner box |

SUS #316 stainless steel |

|||

|

Outer box |

Cold-rolled steel plate + double-sided electrostatic spraying process |

||||

|

Insulation |

Ultra-fine glass wool |

||||

|

Noise |

≤60(dB) |

||||

|

Controller |

7-inch color touch screen controller (with pressure, temperature and humidity, with RS-485 or RS-232 communication, USB data baking) |

||||

|

Resolution |

Temperature: 0.01℃;Humidity: 0.1%RH;Pressure: 0.1 kg/cm²; |

||||

|

Pressurization method |

1. Boiler steam pressurization;2. External gas pressurization |

||||

|

BIAS bias terminal |

Including bias terminal (please specify when ordering optional) |

||||

|

Operating conditions |

Ambient temperature: +5℃~+35℃; Ambient humidity: ≤85%RH;Ambient atmospheric pressure requirement: 86KPa~106KPa |

||||

|

Power supply |

AC220V 50/60Hz |

||||

|

Protection device |

1. Overtemperature protection, 2. Fan overload protection, 3. Chamber door pressure protection, 4. Water shortage protection, 5. Overflow protection, 6. Heater dry burning protection, |

||||

|

Model description |

|

||||

Previous Page